|

<< Click to Display Table of Contents >> Supply Chains |

|

|

<< Click to Display Table of Contents >> Supply Chains |

|

If you've ever played the Beer Game (the System Dynamics version, not other versions you may have encountered), you'll recall the basic premise, representing a supply chain. A product is manufactured, then ordered by and shipped to a distributor, then ordered by and shipped to a wholesaler, then ordered by and delivered to a customer. Only sometimes, there are only three levels. Or five. Real supply chains, of course, involve many parts and sub-assemblies moving through a complex network of suppliers and customers.

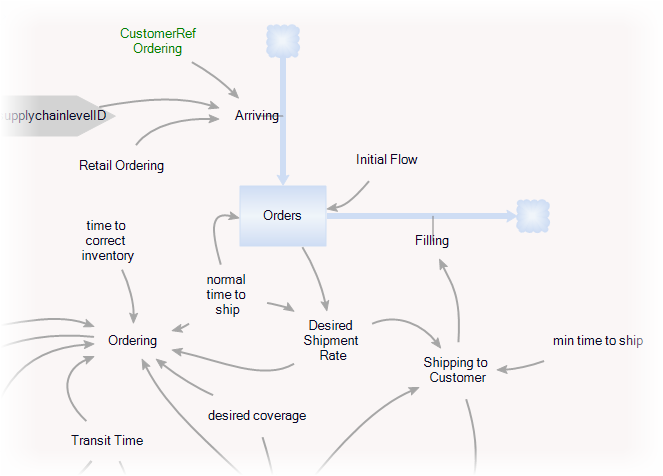

In the Supply Chain 8 model, we have created an entity type that represents any link in a supply chain. The entity receives and fills orders from downstream, then places orders to restore its inventory to a desired coverage level from a supplier upstream (a detail of the entity is shown below).

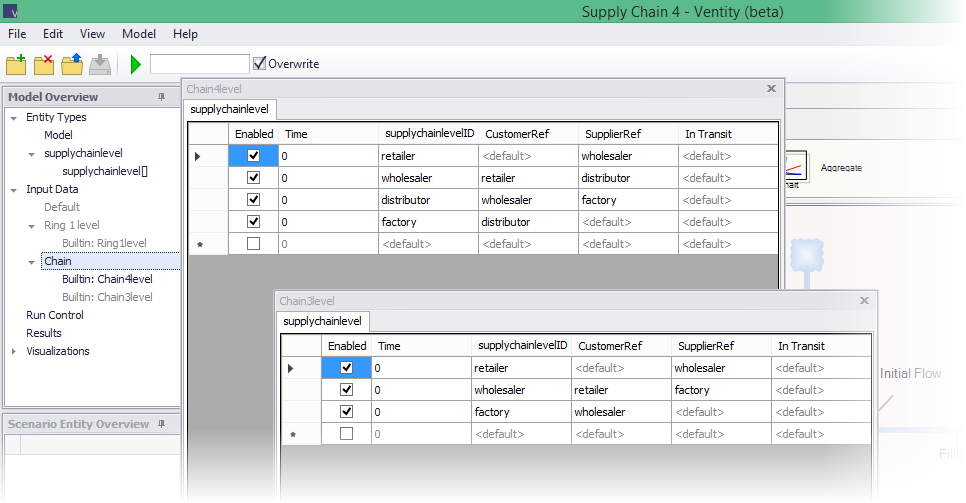

And that's all we have to do. The number of links, or levels, in the chain is determined entirely by the input data. The image below shows two built-in data files, one with four levels and one with three.

To simulate three, simply enable chain3level during initialization. To simulate four, simply enable chain4level during initialization. Or set up both runs in run control and test both configurations against every run. Adding a fifth level is as easy as adding a row.

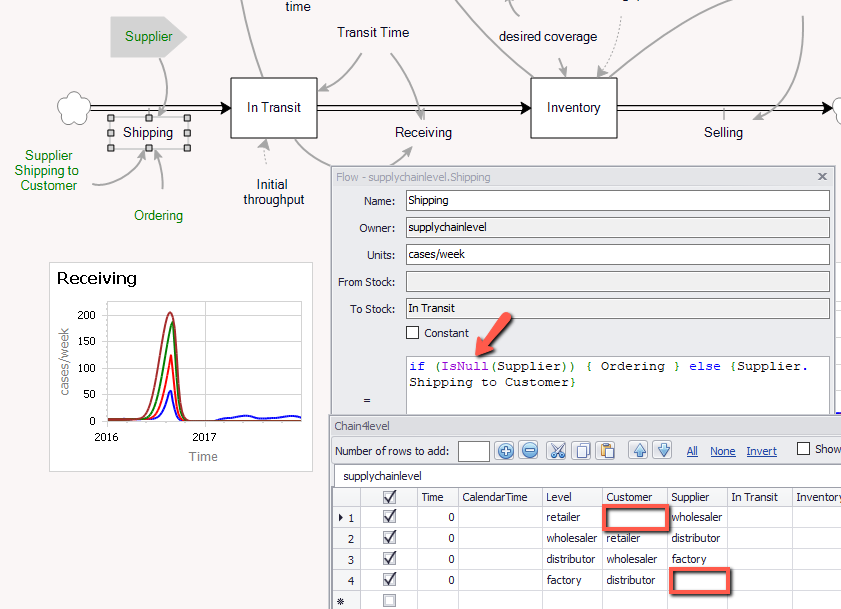

As in the real Beer Game, the ends of the chain are special. The Retailer has no customer entity downstream, and the Factory has no supplier entity upstream. Instead, the Retailer uses an exogenous order input, represented by a deck of cards, and the Factory produces its own product. In the model, this is handled by providing null (empty) inputs in the initialization data, then checking for the empty values with the isnull() function in the model equations:

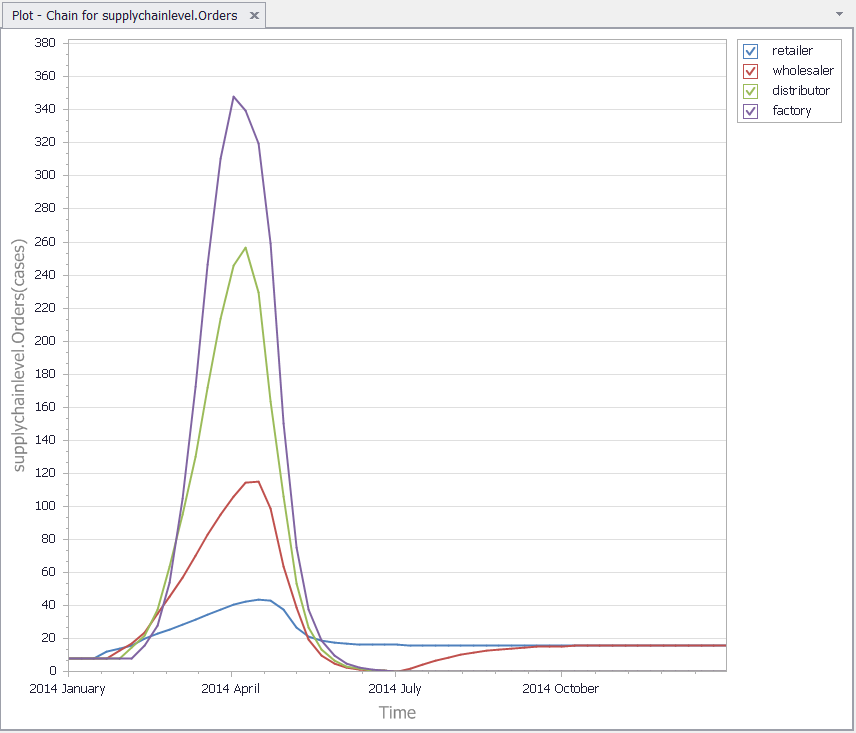

The dynamics of such systems are well understood: a perturbation in orders can create a large over-reaction by suppliers at every level if their inventory forecasts extrapolate from small movements. The plot below shows the orders placed by each of the four levels in the run in response to retail orders moving from 4 to 8 cases per week after the first week.